Why Water Safety Depends on Proper Testing

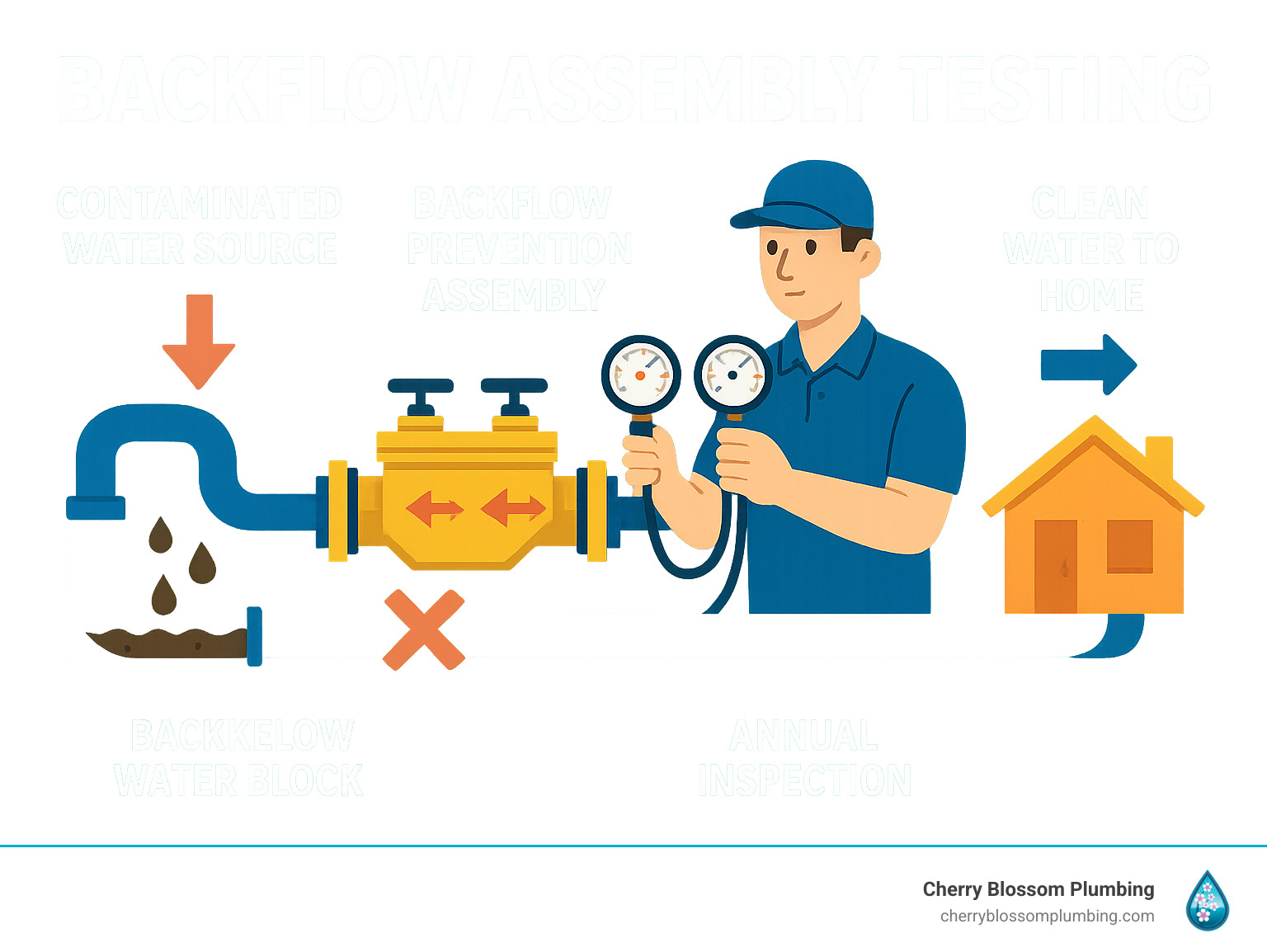

Backflow assembly testing is the annual inspection of devices that prevent contaminated water from flowing backward into your clean drinking water supply. This mandatory testing ensures these mechanical devices are working properly to protect public health and comply with local regulations.

Quick Answer for Backflow Assembly Testing:

- What it is: Annual inspection of backflow prevention devices by certified testers

- Why it’s required: Prevents contaminated water from entering drinking water systems

- Who needs it: Properties with irrigation systems, fire sprinklers, boilers, or commercial water connections

- How often: Once per year, plus after repairs or new installations

- Who performs it: Licensed plumbers with backflow testing certification

- Consequences of skipping: Fines, water service disconnection, and serious health risks

When water flows in the wrong direction, it can introduce hazardous materials like human waste, pesticides, or chemicals into clean water lines. That’s exactly what happened during water main breaks and pressure changes that create dangerous cross-connections between potable and non-potable water sources.

Backflow prevention assemblies use check valves, relief valves, and air gaps to stop this reverse flow. But like any mechanical device, they can fail over time due to debris, worn seals, or valve misalignment.

That’s why annual testing by certified professionals isn’t just a good idea – it’s required by law in most jurisdictions. Cities and water districts mandate this testing to protect the entire community’s water supply from contamination.

Understanding Backflow and Its Dangers

Think of your home’s plumbing like a one-way street for fresh, clean potable water. But when that flow reverses, it’s called backflow. This reversal isn’t just an inconvenience—it’s a serious public health threat that can affect entire neighborhoods.

Backflow occurs when water flows backward through your pipes, potentially mixing contaminated non-potable water with your drinking supply.

The trouble starts at what plumbers call a cross-connection – any point where your clean water system connects to a potentially contaminated source. These connections are everywhere: your garden hose, sprinkler system, even that utility sink in your basement.

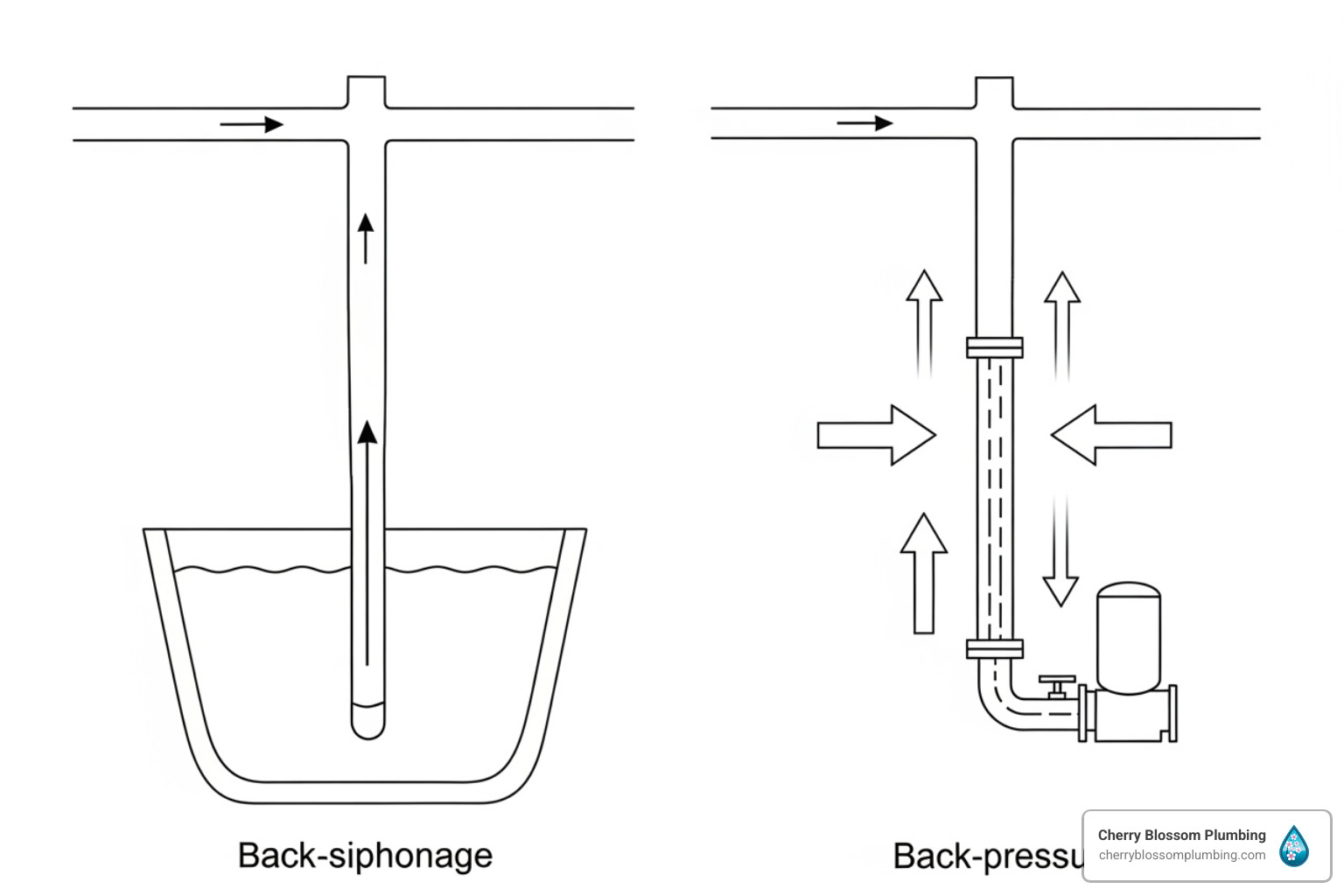

There are two main culprits behind backflow problems:

Back-siphonage happens when water pressure drops suddenly in the main supply line. This creates a vacuum effect, like sipping through a straw, that pulls contaminated water backward into clean pipes. A water main break down the street or firefighters opening hydrants can create this dangerous suction. If your garden hose happens to be sitting in a bucket of fertilizer when this occurs, that chemical cocktail gets pulled straight into your home’s water supply.

Back-pressure is the opposite problem: a contaminated water system builds up more pressure than your clean water supply. Industrial boilers, closed-loop heating systems, and high-pressure irrigation setups can all push their dirty water backward into municipal lines. It’s like trying to merge onto a highway when the on-ramp traffic is moving faster than the main road.

The health hazards from backflow contamination are serious. We’re talking about chemicals from lawn treatments, pesticides from agricultural runoff, human waste from sewer cross-connections, and industrial solvents. These contaminants can cause everything from stomach illness to serious long-term health problems.

That’s why backflow assembly testing exists – to catch these problems before they endanger your family and community. The EPA has documented numerous cases where backflow contamination has made entire communities sick. You can read more about these risks in their report on Potential Contamination Due to Cross-Connections and Backflow and the Associated Health Risks.

At Cherry Blossom Plumbing, we’ve seen how proper backflow prevention protects Arlington and Falls Church families. Our approach to Understanding Backflow Prevention focuses on education first – because informed homeowners make safer communities.

Common Types of Backflow Prevention Devices

Fortunately, engineers have developed several mechanical guardians to protect your water supply. These backflow prevention devices work like one-way valves, allowing clean water to flow forward while blocking any reverse flow.

The Reduced Pressure Zone Assembly (RPZA) is the most robust type of backflow prevention. This device features two independent check valves with a relief valve sandwiched between them. If either check valve fails, that relief valve immediately opens and dumps water onto the ground rather than letting contamination through. You’ll find RPZAs protecting high-risk connections like fire sprinkler systems and industrial facilities.

For lower-risk situations, the Double Check Valve Assembly (DCVA) provides reliable protection with two independently operating check valves. These are simpler and more affordable than RPZAs, making them popular for residential and small commercial buildings. However, they don’t have that safety relief valve, so they’re only suitable where contamination risks are moderate.

The Pressure Vacuum Breaker (PVB) specializes in preventing back-siphonage with its spring-loaded check valve and air inlet valve. These devices are irrigation system favorites, but they must be installed at least 12 inches above the highest water outlet. That’s because they rely on gravity and air pressure to function properly.

The simplest option is the Atmospheric Vacuum Breaker (AVB) – basically a float valve that opens to let air in when water stops flowing. While inexpensive and effective for basic applications, AVBs can’t be tested in the field and aren’t suitable for continuous pressure situations.

Different systems require different levels of protection. Irrigation systems need backflow prevention because they’re constantly exposed to fertilizers, pesticides, and soil contaminants. Fire sprinklers typically require the strongest protection since their water sits stagnant for long periods and may contain fire-suppressing chemicals.

Boilers create both high pressure and chemical contamination risks from treatment additives. Commercial kitchens handle food-grade chemicals and grease that you definitely don’t want in drinking water. Medical facilities, laboratories, swimming pools, and car washes all present unique contamination risks that require proper backflow prevention.

Local plumbing codes determine exactly which type of device your property needs. As your trusted Arlington plumbing professionals, we ensure every installation meets these strict requirements. We truly believe in the Importance of Backflow Prevention for protecting both individual families and our entire community’s water supply.

The Critical Role of Backflow Assembly Testing

Installing a backflow prevention device is only half the battle. These mechanical devices are not “set it and forget it” solutions. Much like a car needs regular tune-ups, these assemblies require annual check-ups to ensure they are still working correctly.

Think about it – backflow assembly testing devices have moving parts, springs, seals, and valves. Over time, debris can sneak in, seals can wear out, and springs can lose their tension. When mechanical failure happens (and it will eventually), your protection against contaminated water quietly disappears. You might not even realize there’s a problem until it’s too late.

That’s exactly why annual testing exists. This isn’t just a nice-to-have service – it’s typically required by law. Most municipal codes mandate yearly testing for properties with backflow prevention devices. Skip this requirement, and you could face fines or even have your water service disconnected.

But beyond avoiding penalties, this testing serves a bigger purpose. When every property owner ensures their backflow preventer is working correctly, we’re all contributing to the safety of our community’s entire water system. It’s like a neighborhood watch program, but for water quality.

The good news? Professional testing catches problems before they become disasters. At Cherry Blossom Plumbing, we’ve seen how proper maintenance keeps these systems running smoothly. Our approach focuses on Effective Backflow Prevention Solutions that give you peace of mind year-round.

What to Expect During a Backflow Assembly Test

When our certified tester arrives, you can expect a thorough yet efficient process. We respect your time and work quickly without compromising safety or accuracy.

The first step involves locating your backflow assembly and doing a visual inspection. We’re looking for obvious issues like leaks, corrosion, or damage that might affect the test results. Our experienced technicians can locate the device if you’re unsure where it is.

Next comes the water shut-off phase. We need to temporarily isolate the water supply to get accurate readings. This usually only takes a few minutes at a time, so you won’t be without water for long. We’ll let you know before we start so you can plan accordingly.

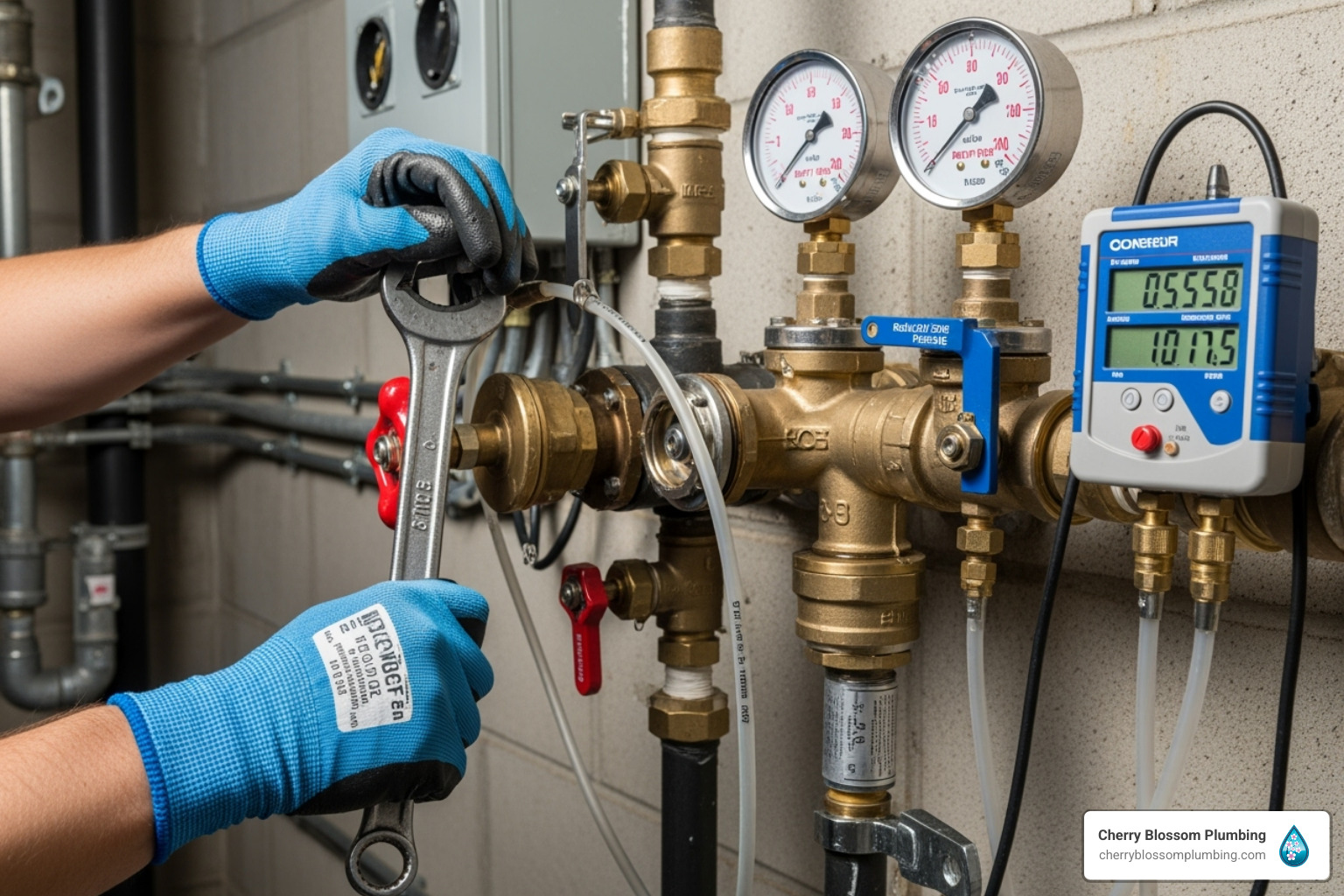

The heart of the testing involves connecting our specialized test kit to the assembly’s test cocks – those small ports you might have noticed on the device. Our pressure differential gauge measures exactly how much pressure each component can handle and whether it’s responding correctly.

During the actual testing, we systematically check each valve’s function. Valve checks ensure the check valves are preventing reverse flow as designed. For devices with relief valves, we verify that the relief valve function activates at the right pressure differential. This step-by-step process follows strict industry standards to guarantee accurate results.

Once testing is complete, we handle all the paperwork for you. We’ll prepare your test report submission and send it directly to your local water authority. You’ll get a copy for your records, proving your compliance with local regulations. The entire process typically takes less than 30 minutes per device – quick, painless, and thorough.

What Happens if Your Assembly Fails?

Nobody likes hearing “your test failed,” but it happens more often than you might think. The important thing is that a failed test is actually good news—it means we caught a problem before contaminated water could enter your system.

Most failures aren’t dramatic catastrophes. Usually, it’s something simple like debris in valves that’s preventing proper sealing. Small particles, mineral buildup, or sediment can interfere with the delicate balance these devices maintain. Sometimes it’s just worn seals that need replacing after years of faithful service.

When a device fails its initial test, we don’t just pack up and leave you hanging. Our first step is typically a clean-and-retest procedure. We’ll carefully disassemble the affected components, clean out any debris, and inspect everything thoroughly. After reassembly, we test again right on the spot. This simple cleaning often gets everything back to perfect working order.

If cleaning doesn’t solve the problem, we often have repair kits available for common issues. These kits contain replacement O-rings, springs, and other components that wear out over time. Our certified technicians carry the most common repair parts, so we can often complete repairs during the same visit.

In cases where the device is beyond economical repair – maybe due to extensive corrosion or age – assembly replacement becomes necessary. We’ll give you honest advice about whether repair or replacement makes the most financial sense. Our goal is always to get you back into compliance as quickly and affordably as possible.

The silver lining? Catching these issues early prevents much bigger problems down the road. Regular testing and prompt repairs help you Avoid Repairs with Backflow Prevention by addressing small issues before they become major headaches.

Navigating Regulations and Finding a Certified Tester

The world of backflow assembly testing regulations can feel like a maze, but we’re here to help you steer it with confidence.

Backflow prevention rules aren’t just suggestions; they are carefully crafted regulations designed to protect everyone’s drinking water, coming from multiple levels of authority. In Virginia, where we proudly serve families and businesses throughout Arlington, Falls Church, and Northern Virginia, these regulations are a team effort between state plumbing codes and your local water authorities.

Your local water authority is typically your first point of contact when it comes to backflow requirements. They’re the ones who know exactly which properties need testing, when it’s due, and what specific devices are required for different situations. The National Plumbing Code provides the foundation, but your municipality fine-tunes the details based on local conditions and needs.

Many cities and counties have established what’s called a Cross-Connection Control Program. Think of this as your community’s water safety watchdog. These programs actively identify properties that might pose contamination risks and ensure proper backflow prevention measures are in place. If you’ve ever received an official-looking letter reminding you about backflow testing, it probably came from this program.

If you get one of these notices, don’t ignore it. These letters are legitimate compliance requirements, not junk mail. Local programs like Fairfax County’s Cross Connection Control and Backflow Prevention Program take water safety seriously, and they expect property owners to do the same.

The good news is that once you understand your local requirements, staying compliant becomes much easier. Most programs send annual reminders, provide lists of certified testers, and even offer guidance on which type of backflow prevention device you need.

Who is Qualified to Perform Backflow Assembly Testing?

Not just anyone with a wrench can perform backflow assembly testing. This isn’t a job for your handy neighbor or the general maintenance person. Water safety is too important to leave to chance, which is why strict certification requirements exist.

To legally perform backflow testing, a technician must be a certified backflow tester. This means they’ve completed specialized training that goes far beyond basic plumbing knowledge. They need to understand the intricate workings of different backflow prevention assemblies, master precise testing procedures, and know how to interpret pressure readings accurately.

Most certified testers are also licensed plumbers, since backflow prevention falls under the plumbing trade. However, having a plumbing license alone isn’t enough – the backflow certification is a separate, additional qualification that requires dedicated study and testing.

The certification process is pretty rigorous, and rightfully so. Candidates must complete a comprehensive backflow tester certification course that covers everything from basic hydraulics to advanced testing procedures. They study different types of assemblies, learn about cross-connection hazards, and practice hands-on testing techniques.

After completing the coursework, aspiring testers face both a written exam and a practical exam. The written portion tests their theoretical knowledge, while the practical exam requires them to actually perform tests on real equipment under supervision. Organizations like the American Water Works Association (AWWA) set industry standards for these certifications, typically requiring a minimum passing score of 75% on both components.

This thorough training ensures that when a certified tester shows up at your property, they have the knowledge and skills to perform accurate tests and spot potential problems. At Cherry Blossom Plumbing, our technicians maintain current certifications and stay up-to-date with the latest testing standards and local requirements throughout Northern Virginia.

Consequences of Non-Compliance

It’s easy to dismiss reminder notices, but the consequences of skipping your annual test can be severe.

Municipal water authorities have real enforcement power when it comes to backflow compliance, and they’re not afraid to use it. The consequences start small but can escalate quickly if you continue to ignore the requirements.

Fines are usually the first consequence you’ll encounter. These aren’t token amounts designed to get your attention – they can be substantial enough to make you wish you’d just scheduled the testing in the first place. Some jurisdictions add these fines directly to your property tax bill, so they don’t just disappear if you ignore them.

But fines are just the beginning. If you persistently avoid compliance, your water provider can take the nuclear option: water service disconnection. Imagine explaining to your family, employees, or tenants that there’s no running water because you skipped a routine test. For businesses, this can mean closing doors until compliance is restored. For apartment buildings, it can create serious habitability issues.

The legal liability aspect is even more serious. If your untested or malfunctioning backflow preventer allows contamination to enter the public water system, you could face lawsuits for damages, cleanup costs, and other legal consequences. The financial impact could be devastating, far exceeding the simple cost of annual testing.

Most importantly, there’s the public health risk that non-compliance creates. When you skip testing, you’re not just risking your own water quality – you’re potentially putting your entire community at risk. A single contamination incident can affect hundreds or thousands of people, causing illness and undermining everyone’s trust in the water supply.

The bottom line is simple: the small investment in annual testing is nothing compared to the potential consequences of skipping it. At Cherry Blossom Plumbing, we make compliance easy and stress-free, helping you Prevent Backflow in Arlington Homes and businesses throughout Northern Virginia. Why risk it when peace of mind is just a phone call away?

Frequently Asked Questions about Backflow Testing

When it comes to backflow assembly testing, we hear the same questions over and over again. And honestly, we love answering them! It means people are taking water safety seriously and want to understand what they’re dealing with. Let’s explore the most common concerns our customers bring to us.

How much does backflow testing and repair cost?

This is usually the first question, and we understand. Nobody likes budget surprises. While we can’t give specific numbers without seeing your setup, we can break down the costs so you know what to expect.

Testing fees cover the actual annual inspection – that’s our certified technician’s time, the specialized pressure gauges and equipment, and filing your compliance report with the local water authority. The fee varies depending on what type of device you have. A Double Check Valve Assembly (DCVA) typically costs less to test than a Reduced Pressure Zone Assembly (RPZA) because the RPZA has more components to check.

If your device doesn’t pass the initial test, repair costs come into play. Sometimes it’s just a matter of cleaning out debris and retesting – no big deal. Other times, we might need to install a repair kit with new seals, springs, or O-rings. The labor involves carefully taking apart the assembly, replacing worn parts, and putting everything back together properly.

Replacement costs are the biggest investment, but they’re only necessary when a device is really old, severely damaged, or keeps failing despite repairs. This includes the new backflow prevention assembly itself, installation work, and any permit fees your municipality requires for major plumbing changes.

We believe in being upfront about all your options and costs before we start any work. No surprises, no pressure – just honest recommendations based on what your system actually needs.

Do I need a backflow preventer for my home’s sprinkler system?

Short answer? Almost definitely yes. If you’ve got an in-ground irrigation system connected to your home’s water supply, local plumbing codes pretty much universally require backflow prevention.

Here’s why: your sprinkler system is a high-hazard cross-connection. Its lines can contain fertilizers, pesticides, and stagnant water. Without proper protection, a sudden pressure drop in the main water line could suck those contaminants back into your kitchen faucet.

Local plumbing codes typically require either a Pressure Vacuum Breaker (PVB) or an RPZA for irrigation systems, depending on the specific setup and local requirements. And yes, once it’s installed, you’ll need that annual testing to keep everything legal and safe.

If you’re in the Fairfax area and wondering about your sprinkler system’s compliance, we can help you figure out exactly what you need. Check out our guide on Backflow Prevention for Fairfax Homes for more local-specific information.

How often does my backflow preventer need to be tested?

The annual requirement is standard across the country, including in Arlington and Falls Church. Your local water authority tracks this, so be sure to mark it on your calendar.

But there are a few other times when testing is mandatory. After installation of any new backflow prevention device, we need to test it to make sure everything was installed correctly and is working as designed. Nobody wants to find out months later that a new device wasn’t functioning properly from day one.

After major repairs is another testing trigger. If we’ve had to replace significant components or rebuild your assembly, it needs to be retested to confirm everything is back to proper working order.

Local jurisdiction rules can sometimes add their own requirements, so it’s always worth checking with your specific water authority. They’re usually pretty good about sending out annual reminder notices, but don’t wait for that letter to show up – it’s better to be proactive about scheduling your testing.

The bottom line is this: regular testing isn’t just about staying compliant with regulations. It’s about making sure your family’s water stays clean and safe, year after year.

Protect Your Water with Professional Testing

Every time you turn on your tap, you expect clean, safe water. It’s a basic part of daily life we often take for granted. Backflow assembly testing is one of those invisible guardians, protecting your family’s health and your community’s water supply from contamination.

Here’s the thing about water safety: it’s not just about your property. When one backflow preventer fails, it can potentially affect everyone connected to that water system. That’s why this annual testing isn’t just a regulatory requirement – it’s our collective responsibility to each other.

Proactive maintenance is always smarter (and cheaper) than reactive repairs. By staying on top of your annual backflow assembly testing, you’re catching potential problems before they become real dangers. It’s like getting your car inspected – a small investment that prevents much bigger headaches down the road.

We know dealing with municipal notices and compliance requirements can feel overwhelming. That’s exactly why Cherry Blossom Plumbing exists. We’re your neighbors here in Arlington and Falls Church, and we understand the local regulations inside and out. Our certified technicians handle everything from the initial testing to submitting reports to your water authority.

Peace of mind is priceless, especially when it comes to your family’s health. When you work with our team, you’re not just checking a box for compliance – you’re actively protecting everyone who drinks water from your property. Whether it’s your family at home, employees at your business, or customers who visit your establishment, clean water matters to all of them.

Community safety starts with individual responsibility. Every property owner who stays current with their backflow testing contributes to the larger goal of keeping our shared water supply contamination-free. It’s one of those rare situations where doing the right thing for yourself also helps everyone around you.

Ready to take the worry out of water safety? Schedule Your Backflow Prevention Service in Arlington, VA with Cherry Blossom Plumbing today. We’ll handle the technical details so you can focus on what matters most – enjoying clean, safe water every day.